SectorTransport, Utilities, Urban

ClientRoad and Maritime Services

LocationTourle Street, Kooragang Island, Newcastle

DurationApril 2016 - July 2018

Contract Value$51.1M

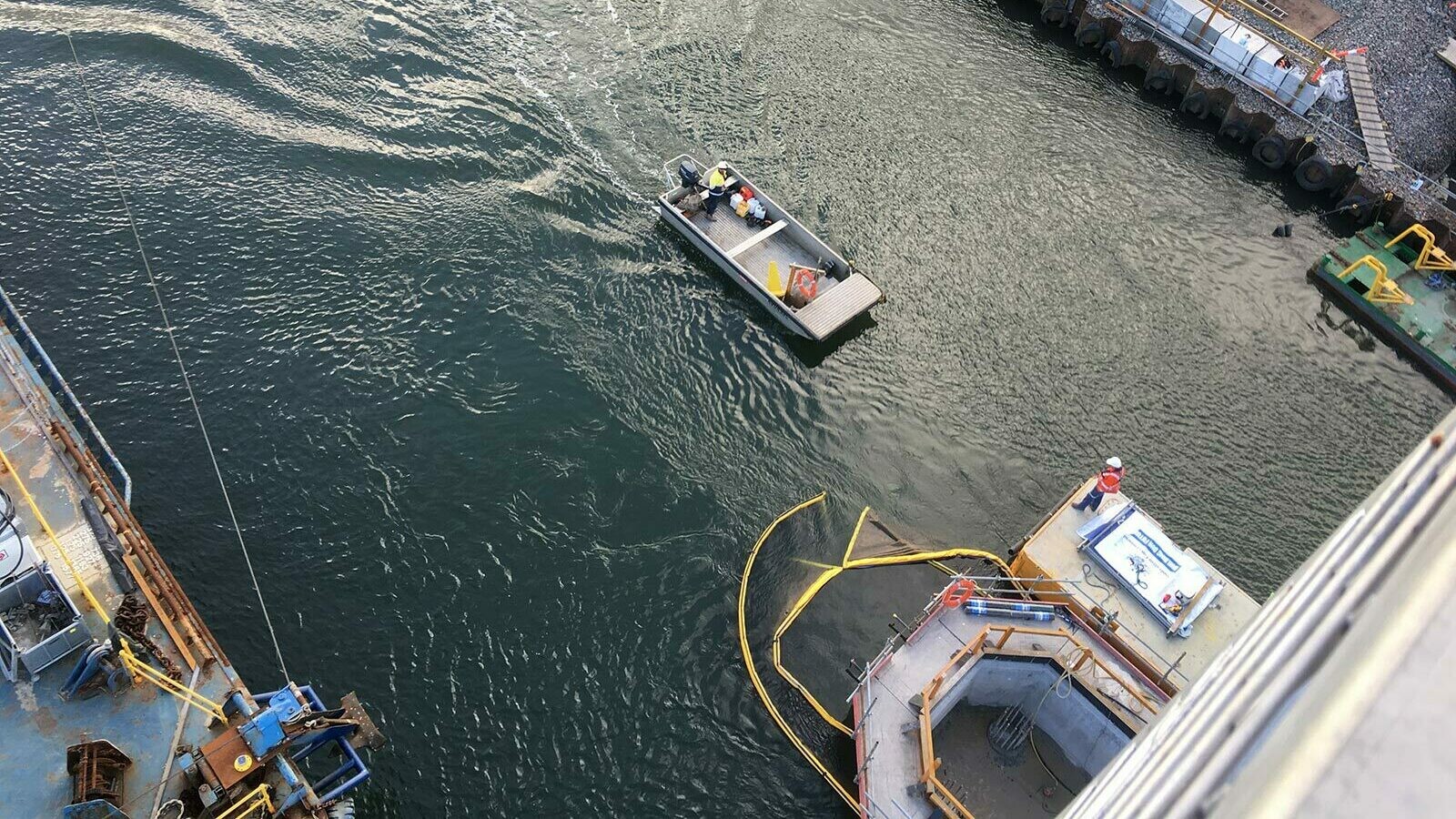

McIlwain and WBHO Joint Venture was awarded the $51M Tourle St & Cormorant Rd duplication in March 2016. The project consists of 3.8kms of road upgrade from single to dual lane carriageway, including a 340m 11 span bridge over the Hunter River, to cater for the 33,000 vehicles which travel along this busy corridor daily.

PROJECT OVERVIEW

340m bridge, 11 spans, 2 lanes

55No x 35m length Super T Girders up to 80t

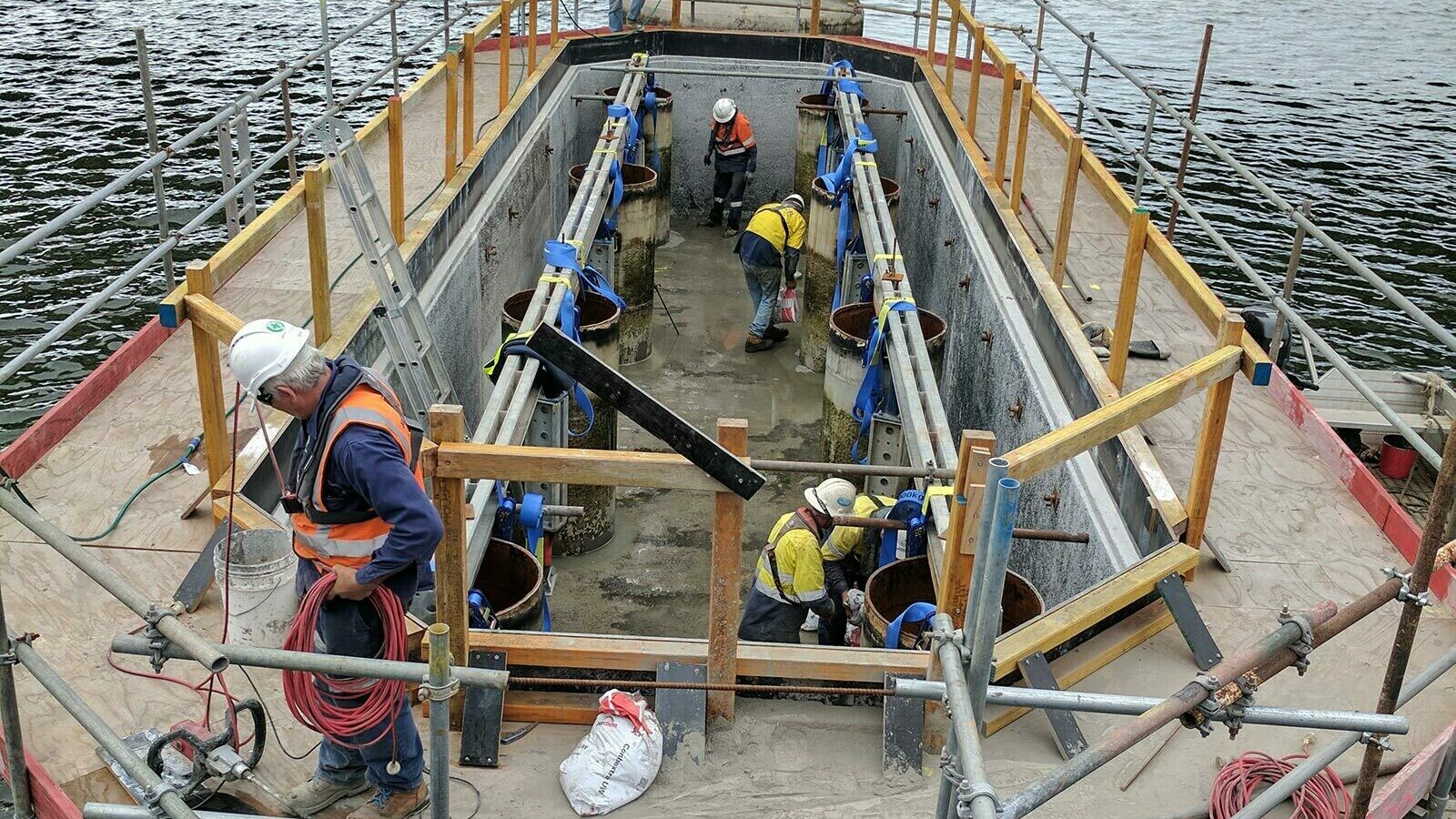

Removal of demolished bridge remnant piles

3.8km roadworks

Widening of Tourle Street and Cormorant Road from 2 to 4 lanes

Retaining Walls & Spillage Traps

Rehabilitate contaminated land

Pre-load/ surcharge embankments

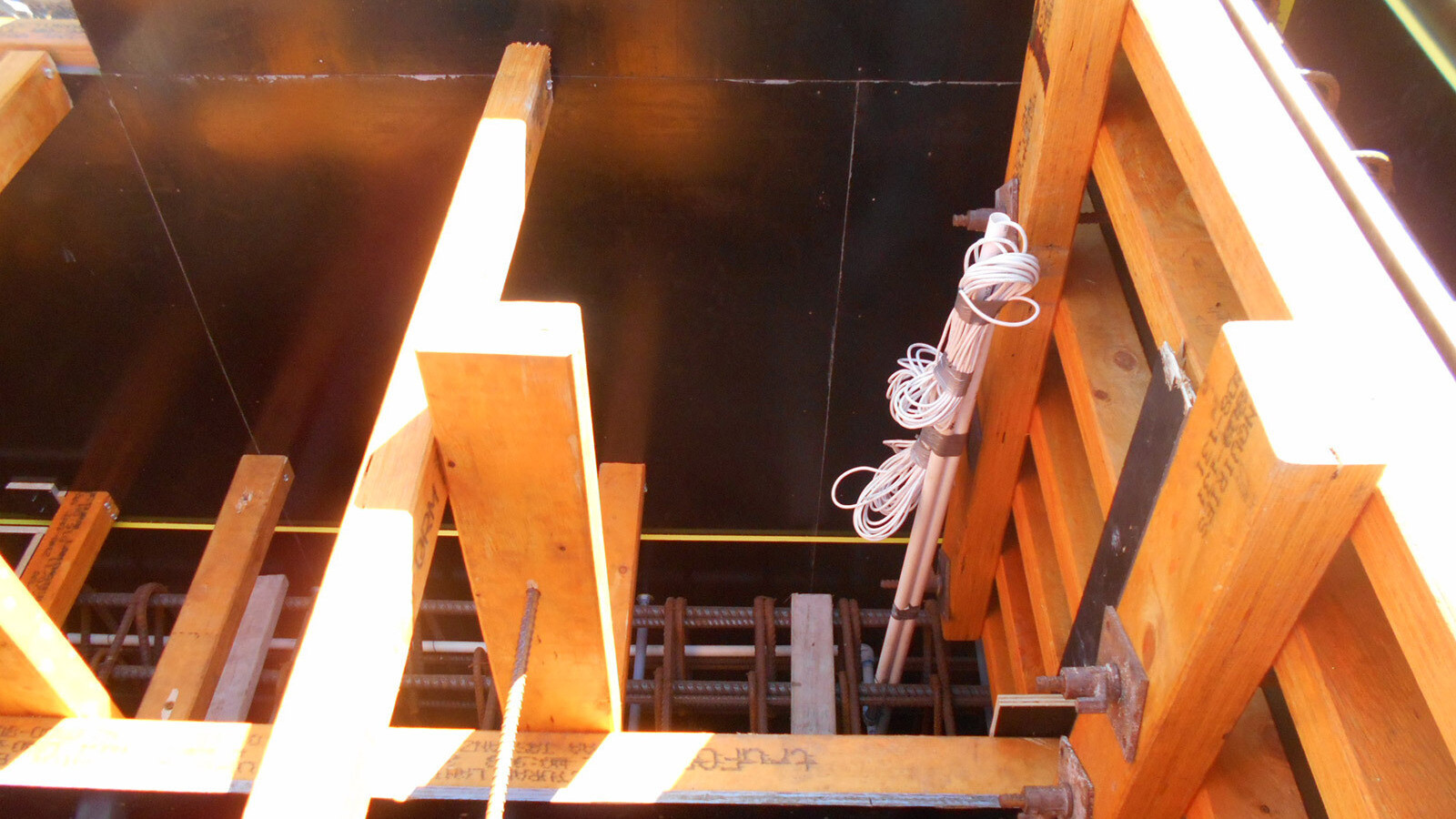

140No x 400sq x 25m long Precast piles

6000 m3 concrete & 1000t steel

10,000 tonnes asphalt

50,000 tonnes HBB (cement modified base)

Water infrastructure 2.5km